2022, silicon carbide semiconductor year one?

800V drive systems are increasingly favored by automakers and suppliers because they can reduce the weight of electric vehicles (EVs), enable faster charging, and ensure a longer driving range. Silicon carbide (SiC) semiconductors are being pushed to the forefront in electric vehicle powertrains and other applications where power density, energy efficiency and reliability are key design considerations.

Silicon carbide is increasingly popular in electric vehicle design building blocks such as traction inverters, on-board chargers (OBCs), and DC/DC converters. In the industrial sector, silicon carbide components are increasingly used in motor drives, renewable energy converters and storage systems, as well as telecommunications and data center power systems.

Figure 1: The high frequency performance of silicon carbide enables the use of smaller passive components in power systems. (Credit: STMICROELECTRONICS)

In view of the potential of silicon carbide in electric vehicles and industrial markets, STMICROELECTRONICS recently launched the third generation STPOWER SiC MOSFET, while claiming that most of its derivatives are commercially ready. According to Edoardo Merli, vice president of STMICROELECTRONICS Automotive & Discrete Group, the company is targeting $1 billion in silicon carbide revenue by 2024.

The advent of third generation silicon carbide technology means that silicon carbide devices with nominal rated voltages from 650V, 750V to 1200V are now available. Design engineers will be able to adopt the technology for a wider range of applications, from ordinary AC line voltages to high-voltage electric vehicle batteries and chargers. SCT040H65G3A, one of the first SiC devices, is a 750V power MOSFET priced at $5.

Beyond the SiC MOSFET

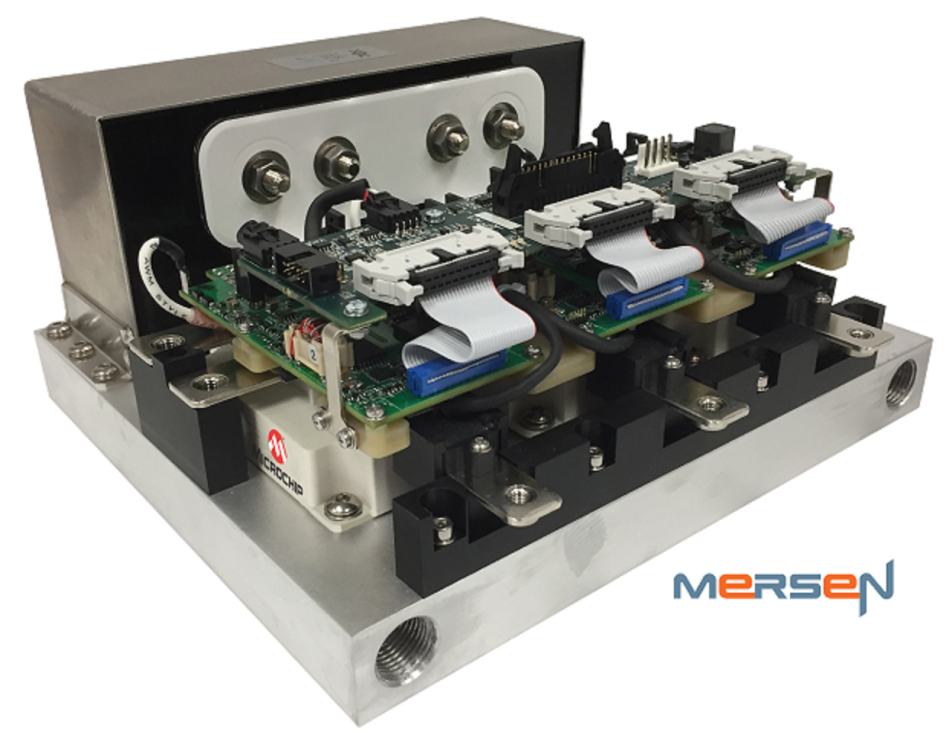

SiC MOSFET has a higher voltage rating and can be used in power modules and reference designs. Microchip, for example, will partner with Power management solution provider Mersen to provide a 150 kVA three-phase SiC power stack reference design for electric vehicles and energy storage applications. The reference design integrates a microcored SiC power module, a digital gate driver, and a Mersen bus, fuse, and capacitor in a single stack reference design.

Figure 2: SiC power stack reduces time to market by up to six months. (Credit: Microchip)

Its power module uses 1,200V MSCSM120AM042CD3AG SiC MOSFET, which works in conjunction with AgileSwitch 2ASC-12A1HP digital gate drivers, enabling design engineers to quickly develop high-voltage systems using kits predesigned for applications. The reference design allows engineers to select voltages from 700V to 1,200V, with currents up to 750A, with the help of a configurable digital gate driver.

The AgileSwitch 2ASC-12A1HP gate driver is powered by Microchip's Intelligent Configuration Tool (ICT), which is available for free download. ICT provides a user interface that allows users to configure gate driver parameters, such as gate switch profiles, system critical monitors, and controller interface Settings.

The reference design built around a SiC MOSFET delivers a power density of 16 kW/l (kW/ L) and Tj up to 130°C, with a peak efficiency of 98% and switching frequency up to 20kHz. The reference design will help optimize any inverter topology, said Philippe Roussel, Vice President of Global strategic Marketing at Mersen. "Silicon carbide is able to expand its main specifications to higher voltages, currents and switching frequencies to meet operating point requirements."

The wide application of SiC devices, from MOSFET to power module to reference design, demonstrates the capability of this wide-band gap technology in electric vehicle applications and fast-charging ev infrastructure. In addition, the energy saving potential of silicon carbide is also driving its industrial applications in solar inverters, energy storage systems, motor drives and power supplies.

Will 2022 be the year of Silicon Carbide Semiconductors?

This article is from the March 2021 issue of Electronic Engineering Album. All rights reserved. Click to apply for a free magazine subscription